“Ventilator”

Assisted

breathing machine

(Translated with www.DeepL.com/Translator)

Daniele Tommei - Digitarch Rome Italy

Rome April - 8 - 2020

The aim was to create a device of simple and economic production, with

basic characteristics and without ambitions of universal adaptability, but

which, although only in the simplest cases, can be useful. This machine, born

to help human beings with breathing difficulties, has been designed to be

easily built with low cost and easy to find components (the cost of all the

necessary parts just over 100 euros). It is necessary to specify, however, that

this machine is not a medical device and has not been certified for any of the

features listed below.

However, despite

the limitations set out above, given the practicality and simplicity of its

operation, we have made this document public so that those who wish to do so

can make it so that they can keep a device at home that they obviously hope

will never have to use.

In this document

and its annexes, all the information necessary for the construction of the fan

will be included, namely: the list of components and their availability, the

construction diagrams (mechanical, electrical and electronic) and the source

code of the software for programming the microprocessor used.

The operating

principle of this machine is based on the intermittent generation of ventilated

air to be inhaled through a nose/mouth mask worn by the patient.

Short video on stand-alone operation

Short movie about the operation in inspiration-controlled mode

(triggered)

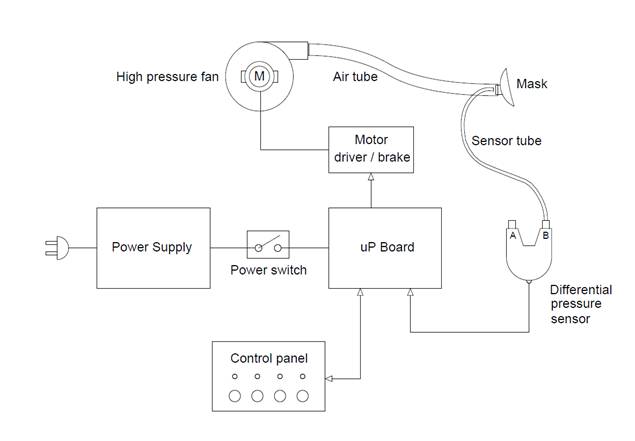

Composition of the

device for assisted ventilation:

The main parts of

this device are:

1) a high-pressure

centrifugal fan

2) a differential

pressure sensor

3. a microprocessor

electronic card

4) a parameter

settings panel

5) a container for

general applications

6) a power supply

adapter

7) a flexible hose

with nose/mouth mask

Description of respiratory ventilator operation

A physiological human

breathing cycle consists of these three phases

-

inhalation

(approx. 1.3-1.5 seconds duration)

-

exhalation

(approx. 2.5-3 seconds duration)

-

short pause between exhalation and inhalation (approx.

0.5 seconds)

The natural action

of inhalation occurs through the enlargement of the chest cavity obtained through

the action of the different inspiratory muscles.

In case the patient

has difficulty in activating the inspiratory muscles to enlarge the costal arch

and thus expand the volume of the lungs to inhale the air, the respiratory

ventilator can help by directly introducing the air into the lungs, determining

the expansion and thus lightening the load on the inspiratory muscles.

This intake of air

must be synchronized with the first spontaneous muscle movement of inspiration

by the patient.

Specifically, the

mechanism of operation is as follows:

As soon as the

patient tries to breath in, a depression, albeit minimal, is generated in the

lungs, which is detected by the pressure sensor in the mask. The signal

detected by the sensor is transmitted to the ventilation device which

immediately generates the pressurized air that is injected into the lungs. Once

the air supply phase is complete, the ventilator stops and the patient can

automatically exhale air from the lungs in the following seconds. In this

second phase it is the lungs themselves which, without any muscular aid by

virtue only of their elasticity, expel the air contained in them.

At the end of the

exhalation phase, the natural breathing cycle starts again and with it also the

action of the ventilator. With this system, the air is introduced into the

lungs synchronously following the patient's natural breathing cycle.

The ventilator will

work even if the patient does not have the ability to begin the inhalation

phase independently. In fact, the ventilator is equipped with a timer that will

make it operate in any case, i.e. even if no inhalation attempt signal is

detected. In this hypothesis, the ventilator will still supply air into the

lungs after the period set in the timer has elapsed.

This concerns the

operation of the fan with detection mode activated. However, it is possible to

set the fan to autonomous mode.

In this mode, the

ventilator will introduce air into the lungs at regular intervals, regardless

of whether or not the sensor detects signs that breathing has begun. Of course,

this mode will be used in extreme cases where the patient is not in a condition

to stimulate assisted breathing.

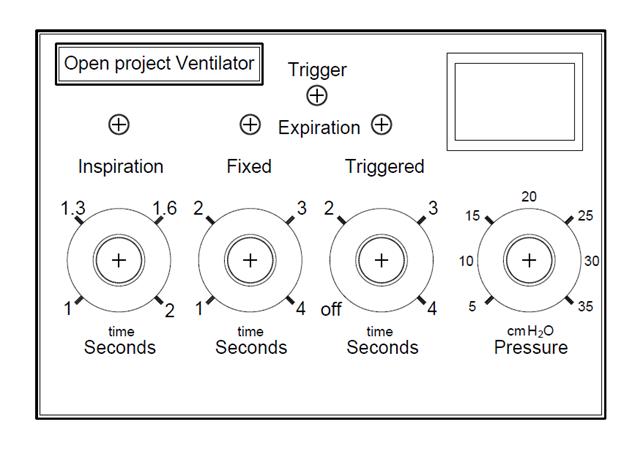

Control

panel: settings and indicators

On the front control panel there are four knobs, a switch, and four LED

indicator lights.

-

The red knob

(Inspiration) allows you to set the inspiration time. The adjustable value

ranges from 1 to 2 seconds and determines how long the ventilator will generate

the continuous flow of pressurized air to be sent to the patient's mask.

-

The red led above this knob indicates that the fan is

in action.

-

The white knob (Expiration Fixed) determines the

duration of the expiration period. The value can be set from 1 to 4 seconds and

during this period the ventilator will not produce airflow allowing the patient

to exhale the air contained in the lungs.

-

The green led above this knob indicates that the fan

is stopped and we are in the air exhalation phase.

-

The orange-colored knob (Expiration Triggered)

determines the maximum waiting period during which the ventilator is still

standing waiting for a patient's inspiration. As soon as the ventilator detects

an inhalation stimulus (red trigger LED) within this period, ventilation starts

immediately. If no inhalation stimulus occurs within the set period (can be set

up to 4 seconds) the ventilator will still start and a beep will sound to warn

the caregivers that the patient has not been able to inhale on his own.

-

If this orange knob is set to zero (off) the

ventilator will not wait for the inspiratory stimulus but after the previous

expiration phase (the green LED) the ventilator will start immediately.

-

- The yellow led above this knob indicates that the

fan is waiting for an inspiratory stimulus to activate the fan and generate

pressurized air.

-

The red Trigger LED sends a light signal when negative

air pressure is detected (patient attempt to inhale) during the

"Triggered" Expiration period set via the orange knob. If this knob

is set to "off" the Trigger led will not be activated.

-

The fourth knob, the blue knob (Pressure), determines

the maximum air pressure exiting the ventilator. The pressure value can be set

from 5 to 35 cm. of H2O (from 0.5 to 3.5 KPa).

-

The top right 0/1 switch controls the power on of the

device.

Description

of parts and operation diagram

This assisted

breathing device consists of these four main functional parts:

the fan, the pressure sensor, the microcomputer, the

control panel.

The

first of these is a high-pressure centrifugal fan.

This is driven by a

DC electric motor. The function of this fan is to suck air from outside,

pressurize it and send it through a hose to the mask worn by the patient. The

fan is called a high pressure fan because it produces significantly more

"pressurization" of the air than a normal fan.

The high pressure,

although not that high, must be at least about 20 cm. of H2O to ensure that it

is sufficient to "inflate the lungs".

To obtain this

characteristic, this type of fans have an impeller that rotates at a very high

speed, normally higher than 10,000 rpm and for this reason they must be well

constructed and balanced to minimize vibrations and noise produced.

In this project, at

the moment, the low cost has been privileged and therefore a very cheap fan (less

than 10 Euro) easily available because used in a common 12V inflator for

inflatable boats has been used. This

fan, in the test that we have carried out, comes to produce a pressure (with

zero flow) of 35 cmH2O. To obtain this

pressure, however, you need a 12V. power supply that can support at least 4A.

continuous (the one supplied does not exceed 2A.).

The impeller of

this fan can rotate at different speeds depending on the voltage applied to its

motor. Since the pressure of the air flow generated by the fan is a function of

the rotation speed, adjusting the electrical voltage on the motor will regulate

the air pressure generated.

The

second functional part, of this breathing machine, is the pressure sensor.

Inside the air

transport tube, which goes from the fan to the mask, a second thinner tube has

been inserted to measure the pressure of the air sent. This small tube runs

along the entire length of the larger tube where the air passes, starting from

the fan and ending up at the plug on the mask.

While on the mask

side this small tube is left open and not connected to anything, on the fan

side it is connected to a differential pressure sensor.

The other input, of

the two inputs of the pressure sensor, is left open inside the box and not

connected to anything (actually it is not true that it is not connected to

anything: it has been left free just to measure the pressure inside the box).

This differential

sensor has the task of measuring the pressure difference between its two inputs

and transforming it into a signal that will indicate to the microcomputer what

is the difference in the air pressure value between the inside of the box

(which is actually the same as the ambient pressure) and the air inlet in the

mask.

It was considered

appropriate to extend the measuring tube up to the mask to improve the accuracy

of the air pressure measurement.

If in stationary

air conditions the pressure is always the same at every point of the tube, with

the air in motion there will be a pressure difference due to the pressure drop

between the beginning of the tube, connected to the fan, and the end of the

tube connected to the mask. In addition, the proximity of the measurement point

to the patient's mouth/nose improves the accuracy and speed of the ventilator's

response to the patient's inhalation attempt.

The differential pressure sensor has two functions:

-

The first function is to measure the positive pressure

of the pressurized air generated by the fan during the patient's inhalation

phase, which must remain within the limits set on the control panel. In this

phase the microcomputer will adjust the speed of the fan impeller to not exceed

these limits.

-

the second function is to detect the first inhalation

stimulus immediately after the exhalation phase. In a certain period of time,

which can be set from the control panel, the sensor will detect if there is a

rapid drop in pressure, following the patient's inhalation stimulus, and the

microcomputer will then immediately activate the generation of pressurized air

to help the patient to inhale.

The sensor used is

the MPX5010DP model available from RS-Components or other distributors of

electronic components, and has a flow rate up to 10KPa, i.e. 100 cm. of H20,

more than enough for the pressures in play that should never exceed 3.5KPa.

The

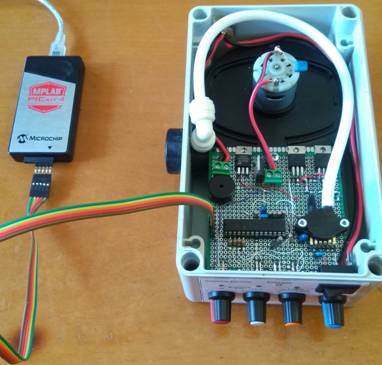

third functional part is the microcomputer.

A Pic16F series

micro from Microchip was used for this device. The model chosen is the 16f1718

in DIP version, which already has inside it all the functional modules needed

for this assisted breathing device such as CLOCK, ROM, RAM, ADC, PWM, etc..

The microcomputer

can be programmed from any PC through a special interface such as PICKIT3 or

PICKIT4. The development system is MPLABX and can be downloaded free of charge

from the Microchip website. The program has been written directly in machine

code (MASM) and is documented among the attachments.

The microprocessor

is mounted on a prototype circuit board and does not currently have a dedicated

PCB. On the board together with the micro, all other electronic components

necessary for operation are assembled, as shown in the attached wiring

diagram. For the 12V. power supply of

the circuit, the same mains adapter supplied with the inflator has been used,

but of course it is advisable to purchase a more robust one such as the one

indicated in the list of the main parts needed.

It would also be advisable to connect a 12V. buffer battery of at least

10Ah, or alternatively use an uninterruptible power supply for computer to

ensure operation even in the event of a power failure.

The

fourth and last functional part is the control panel.

The panel simply

consists of 4 knobs and 4 LEDs, in addition to the power switch and a buzzer

inside the box.

At the moment we

have decided to keep to a minimum all the possible options and variables that

can be used to adapt the device to more particular cases, favouring simplicity

and easy management even by a home healthcare service.

The 4 knobs

regulate 4 different potentiometers connected to the microcomputer and set the

necessary parameters for the desired operation. The 4 leds, and the acoustic

signaller, also connected to the microcomputer, signal the different states of

operation to help and monitor the correct adjustment of the parameters.

List of main parts

High pressure inflator, complete with 12V 2A adapter

https://www.amazon.it/gp/product/B07QQXV74M

A plastic container

(180x110x90)

https://it.rs-online.com/web/p/contenitori-per-applicazioni-generiche/0832649/

https://it.rs-online.com/web/p/contenitori-per-applicazioni-generiche/0220440/

-

Microprocessor

Microchip Pic 16F1718 (DIL 28 pin)

https://it.rs-online.com/web/p/microcontroller/8417541/

pcb for prototypes

https://www.amazon.it/ELEGOO-Millefori-Prototipo-Circuito-Prototype/dp/B073WR78M6

-

Pressure

differential sensor NXP mod. MPX5010DP

https://it.rs-online.com/web/p/sensori-di-pressione/7191080/

-

Potentiometers

and knobs

https://www.amazon.it/GTIWUNG-Potenziometro-Rotativo-Regolabile-3-Terminale/dp/B07WQG1RNZ

-

Programmer

for Microchip microprocessor

https://www.amazon.it/ARCELI-PICKIT3-Simulator-Programmer-Emulator/dp/B07BP65KQD/

-

Power

supply 12 V. 7.5A

https://www.amazon.it/Caricabatteria-Adattatore-Alimentatore-Pico-PSU-Connettore/dp/B07588717M/

-

Washing

machine extension hose

https://www.amazon.it/Xavax-HAMA-Prolunga-scarico-metri/dp/B003ZYRN1M/

-

Mask

https://www.amazon.it/gp/product/B00P3YRRMC

Mechanical construction

To separate the fan

from the inflator, simply remove the two screws on the rear cover. Then we

desolder the electrical connections. From the inflator we also recover the

switch and the power connector.

The box we used is

very small but still allowed to contain everything you need. Of course it is

possible to use larger ones.

After drilling the

box both at the bottom and at the side with a 31 mm diameter cup drill, we

shape and drill a rectangle of 6-8 mm thick pvc forex to fix it at the bottom

of the box.

With the help of

the attached template we can drill the holes on the front for the

potentiometers, the LEDs and the on/off switch

At this point we

can try to insert the fan and adapt the slots if necessary

We assemble the

electronic circuit adapting the size of the multi-hole PCB and solder the

potentiometers on the bottom side and the LEDs and the rest of the components

on the top side

The circuit shown

is the prototype and therefore the connections have been made with wires

The board will be

fixed on the front side of the box by the same potentiometers.

On the back edge,

the card has been fixed directly to the fan through one of the holes already

present on the fan.

On the rear edge of

the box the power connector has been inserted, while on the front side the

On/Off switch has been inserted (both taken from the inflator).

A 6 mm hole has

been drilled in the outlet of the fan, into which a tube of a few centimetres

is inserted as shown. This is the pressure sensor that will be brought up to

the mask. On the inside of the box the small tube, through a 90° connection,

will be connected to the pressure sensor on the side indicated, corresponding

to pin 6 (the other inlet must be left open). On the external side of the box,

a metal tube is inserted into the control line, which will be the connection

with the rest of the control line that will go to the mask.

The small tube,

passing inside the main 30 mm air tube, will come close to the mask worn by the

patient. In this way, the measured pressure will be exactly the pressure that

is inhaled by the patient. In addition, the time required to detect the

pressure drop induced by the inhalation attempt and thus the subsequent start

of the ventilator is reduced to a minimum.

The air hose

connected to the respirator is connected to the fan using a piece of common PVC

hydraulic hose and heated to widen the internal diameter to about 30.5 mm.

At the other end of

the pipe, the connection with the template is obtained by means of a fitting.

A second inlet can

also be seen on the mask to which the oxygen tube to the cylinder or to an

oxygen concentration machine can optionally be applied if necessary.

Technical notes on future

features and improvements

The heart of this device is the pressurized air

generation system. A small fan with DC brush motor has been used in this

machine to perform this function. This choice was dictated mainly by the easy

availability and low cost, but of course at the expense of the features. The

critical points of this type of fan are the noise, the not very high pressure

and the inertia in reaching the necessary rotation speed, which results in a

delay in the generation of pressurized air from the moment the demand is activated.

We have tried different types of commercial fans and

are testing others. The best choice will be to use a fan with a small impeller,

but with very high speeds above 30,000 rpm. Fans of this type use a brushless

motor. Unfortunately these fans, besides

being more difficult to find, are more expensive and require additional circuit

complexity for their operation. The model that could be a perfect replacement

for the current fan is the WM7040 which can reach a pressure of more than 60

cmH2O. This model, equipped with its driver board, can be easily inserted into

the current circuit, using the PWM signal that currently arrives at the gate of

the power mosfet IRLZ44 as a speed control.

The programming software

for the microprocessor has been developed on the MPLABX platform of the

Microchip (downloadable free of charge from their website) using a personal

computer with Windows. The control

program for the uP was written directly in the microchip's native code. For the

programming then a five-pole cable is used that directly accesses the micro via

a connector on the board. We used the PICKIT4 programmer but any other

programming system compatible with this uP family can be used. All source code

is included in the attachments of this project.

The code is not

very complex and can be easily modified to suit different needs.

Below is the

flowchart that summarizes the control mechanism of the uP. on the

interconnected hardware.

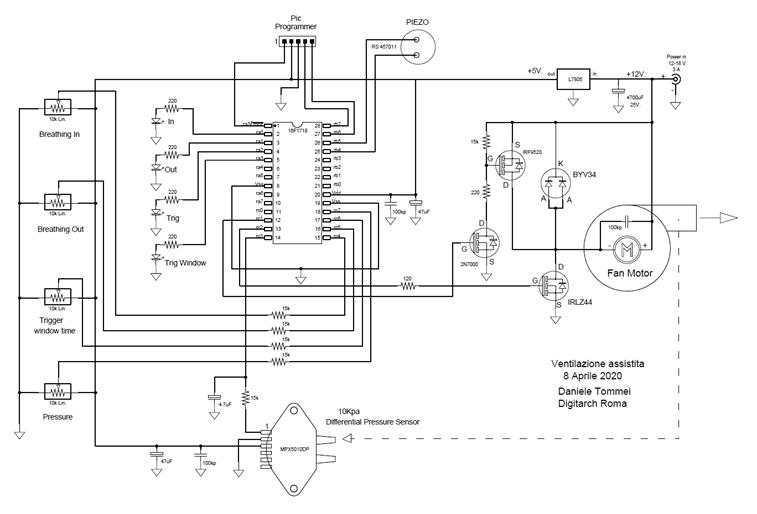

Description

of electrical operation

The circuit is

based on an in-line programmable microchip uP with internal clock set at 16

Mhz. The control circuit consists of 4 optical signalling leds and 4

potentiometers that provide 4 values from 0 to 5V. on the inputs of the uP and

a piezo acoustic signaller.

The power supply is

predisposed for a voltage of 12V. for an absorption of about 4 amperes of

current. The voltage of the logic part is 5V. and is generated by a linear

stabilizer L7805.

The fan speed is

controlled by the IRLZ44 N channel mosfet which is directly driven on the gate

by an output of the uP 16F1718. The current of this output is sufficient to

guarantee a switching time of less than 2 uS, short enough to use a PWM signal

with a cycle of 250 uS (4 Khz.)

IRLZ44 Mosfet Gate signal

In parallel to the

motor a fast BYV34 diode is used as "freewheeling" for current

recovery. Also in parallel to the motor a P channel mosfet has been used to

short circuit and brake the motor itself, reducing the deceleration phase time

when the fan must be stopped quickly.

The MPX5010

differential pressure sensor produces a ratiometric voltage ranging from 0 to

the supply voltage (5V.) depending on the pressure difference between the two

pneumatic inputs. With an equal pressure on the two inputs the output voltage is

about 0.5V while with a difference of 10KPa (100 cmH2O) the voltage is about

4.5V It should be noted that the sensor can detect even a slight negative

pressure bringing the 0.5V output up to 0V.

The sensor is

connected through a small tube to the fan outlet in order to measure the

pressure in reference to the ambient pressure, detected by the second sensor

input left free.

Pressure value on the sensor output

In the image above we can identify the air intake phase (steep climb)

and the exhalation phase (asymptotic descent) followed finally by the negative

pressure trigger phase.

All attached documentation (in

English) can be found here:

For information, suggestions

or other requests you can email to:

home page:

http://digitarch.net/Ventilator.htm